-

-

Colleges

-

-

Student Experience Greek Life Housing & Dining Health & Recreation Our Campus Community Engagement Athletics

-

Capabilities

Additive Manufacturing

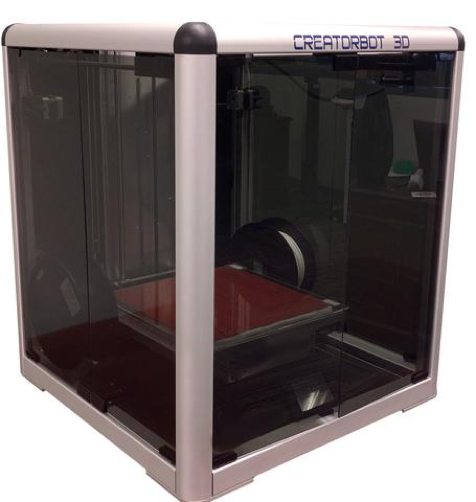

- CreatorBot 3D Pro Series II

The CreatorBot 3D by 3D Printerworks is a fused deposition modeling (FDM) desktop 3D printer. This machine is equipped with a dual extruder which enables the printer to use a soluble support structure for easy support removal. The CreatorBot comes with several features like filament out detection, automated platform leveling, and a quick change build plate. These features make this 3D printer user friendly and easy to use.

Tech. Specs.

- Build Volume: 12 x 12 x 18 in (305 x 305 x 457 mm)

- Filament diameter: 1.75 mm (0.069 in)

- Print Resolution 50-400 micron (1.97-15.7 in)

- Size: 22.5 x 24.5 x 28 in (57 x 62 x 71 cm)

- Weight: 65 lb (30 kg)

Image

- Epilog Zing 16 Laser

The Epilog Zing Laser is a machine that utilizes a process called subtractive manufacturing, as opposed to additive manufacturing, or 3D printing. The laser is perfect for engraving materials like wood, acrylic, ceramic, glass, marble, and many others with very high quality and precision. In addition to engraving, or rastering, the Epilog Zing 16 Laser can also vector cut certain materials. This apparatus is extremely reliable and quick, rendering precise and accurate engravings.

Tech. Specs.

- Weight: 95 lb (43 kg)

- Engraving Area: 16 x 12 in (406 x 305 mm)

- Maximum Material Thickness: 4.5 in (114 mm)

- Laser Wattage: 30 or 40 watts

- Memory: File storage of up to 64 MB

- Size: 28.75 x 22.125 x 11.75 in (730 x 562 x 298 mm)

Image Image

Image

- ExOne M-Flex

The ExOne M-Flex 3D printer utilizes binder jetting technology in order to create prototypes made out of metals. This machine offers the freedom of producing complex geometries that requires no support structures. The models created from the M-Flex are very accurate and reliable. The products generated from this 3D printer also require no tooling, which is what makes binder jetting such an important aspect of additive manufacturing.

Tech. Specs:

- Build Volume (LxWxH): 15.7 x 9.8 x 9.8 in (400 x 250 x 250 mm)

- Build Speed: 30-60 seconds per layer

- Layer Thickness: Variable with minimum of 0.002 in (50 μm)

- Print Resolution (X/Y/Z): 0.003/0.002/0.004 in (63.5/60.0/100 μm)

- Printable Materials: Stainless steel, bronze, Alloy IN 625, iron, or tungsten

- Size (LxWxH): 66 x 55 x 73 in (1,675 x 1,400 x 1,855 mm)

- Weight: 2,250 lb (1,020 kg)

Image

- ExOne X-1 Lab

The ExOne X1-Lab is a 3D printer created for research and educational purposes. This machine is capable of producing metallic, ceramic, and glass models using an additive manufacturing process called binder jetting. This process requires the layer-by-layer deposition of metallic, ceramic, or glass powder which is then held together by an adhesive material. The X1-Lab is capable of producing professional-grade prototypes which accuracy and precision.

Tech. Specs:

- Build Volume (XxYxZ): 40 x 60 x 35 mm (1.57 x 2.36 x 1.38 in)

- Layer Thickness: Variable down to 50 microns (0.002 in)

- Materials: Metallic powder and ceramic Powder

- Size (LxWxH): 965 x 711 x 1,066 mm (38 x 28 x 42 in)

- Lulzbot Taz 6

The LulzBot TAZ 6 is a fused deposition modeling (FDM) desktop 3D printer that creates professional-grade models. This is a reliable machine that possesses one of the larger build volumes available at YSU. The LulzBot TAZ 6 uses several materials like PLA (polylactic acid), ABS (acrylonitrile butadiene styrene), Polyester, and many more in order to produce 3-dimensional prototypes. This 3D printer comes equipped with several features like a large print volume, a heated build plate, and automatic bed leveling which ensures an accurate build.

Tech. Specs:

- Build Volume (LxWxH): 11.02 x 11.02 x 9.8 in (280 x 280 x 250 mm)

- Top Print Speed: 7.9 in/s (200 mm/s)

- Average Print Speed: 1.18-1.97 in/s (30-50 mm/s)

- Layer Thickness: 0.002-0.02 in (0.050- 0.5 mm)

- Filament Size: 0.1 in (3 mm)

- Standard Software: Cura LulzBot Edition

- Size: 26 x 20.47 x 20.47 in (66 x 52 x 52 cm)

- Weight: 43 lb (19.5 kg)

- Makerbot Replicator 2

The MakerBot Replicator 2 uses fused filament fabrication technology to create professional-grade models. This 3D printer uses a plastic called polylactic acid (PLA) as the build material in order to produce accurate prototypes. The Replicator 2 printers make up two of the three MakerBot machines in the lab. While these 3D printers have a smaller build plate than our other machines, the Replicator 2 is capable of creating effective models.

Tech. Specs:

- Material: PLA plastic

- Build Volume (LxWxH): 11.2 x 6.0 x 6.1 in (28.5 x 15.3 x 15.5 cm)

- Layer Resolution

- High: 100 microns (0.0039 in)

- Medium: 270 microns (0.0106 in)

- Low: 340 microns (0.0133 in)

- Positioning Precision

- X&Y: 11 microns (0.0004 in)

- Z: 2.5 microns (0.0001 in)

- Filament Diameter: 0.069 in (1.75 mm)

- Size (LxWxH): 19.1 x 12.8 x 14.7 in (49 x 32 x 38 cm)

- Weight: 25.4 lb (11.5 kg)

- Software: MakerBot MakerWareTM Bundle 1.0

- Makerbot Replicator 2X

The MakerBot Replicator 2X is a desktop 3D printer that is useful for creating quick and professional-grade models. A key feature on this FDM (fused deposition modeling) machine is its dual extrusion head which allows for prototypes to be built using two different materials. This feature is best used with MakerBot ABS (acrylonitrile butadiene styrene) plastic and Dissolvable Filament. Dissolvable filament makes for the easy removal of support structures leaving a near faultless model.

Tech. Specs:

- Build Volume (LxWxH): 9.7 x 6.0 x 6.1 in (24.6 x 15.2 x 15.5 cm)

- Layer Resolution: 100 microns (0.0039 in)

- Filament Diameter: 1.75 mm (0.069 in)

- X&Y Positioning Precision: 11 microns (0.0004 in)

- Z Positioning Precision: 2.5 microns (0.0001 in)

- Software: MakerBot Desktop

- Size (LxWxH): 19.1 x 12.8 x 20.9 in (49 x 32 x 53.1 cm)

- Weight: 27.8 lb (12.6 kg)

- ProJet 1200

The ProJet 1200 is a 3D printer that uses a process called stereolithography. This process is capable of producing very precise and high definition models using digital light projection. The models produced using the ProJet 1200 are made using 3D Systems’ VisiJet FTX materials which are durable and rigid which make them perfect for prototyping. This machine works great for small parts that are rich with detail and require accuracy for generating.

Tech. Specs.

-

Build Volume (XxYxZ): 1.69 x 1.06 x 5.90 in (43 x 27 x 150 mm)

-

Resolution: 56 microns

-

Layer Thickness: 0.0012 in (0.03 mm)

-

Size (WxDxH): 9 x 9 x 14 in (230 x 230 x 362 mm)

-

Weight: 20 lb (9 kg)

-

- ProJet 3510 SD

The ProJet 3510 SD is a professional 3D printer that is capable of generating incredibly accurate, high definition models and prototypes using material jetting technology. This 3D Systems printer uses VisiJet M3 material in order to create ABS-like prototypes in a variety of colors. This apparatus creates the most precise models available on YSU’s campus. The 3D printer is useful for functional testing, rapid prototyping, and generating durable models, all while keeping those models true to their computer-generated designs.

Tech. Specs.

- Build Volume (XxYxZ): 11.75 x 7.3 x 8 in (298 x 185 x 203 mm)

- Resolution: 375 x 375 x 790 DPI (XxYxZ); 32µ layers

- Accuracy: 0.001-0.002 in/in (0.025-0.05 mm per 25.4 mm) of part dimension

- Size (WxDxH): 29.5 x 47 x 59.5 in (749 x 1,194 x 1,511 mm)

- Weight: 711 lb (323 kg)

- Noise: Under 65 dB

- RepRap Metal 3D Printer

The RepRap is an open-source 3D printer that uses welding technology to create three-dimensional, metal prototypes. The draw of this printer is that it is designed to exclusively print parts out of metal, is a field that is mostly run by plastic materials. This machine is currently being worked on at YSU, so it is a work in progress. The RepRap works differently from other printers in that the point of material deposition does not move, and the platform onto which molten metal is deposited is responsible for all motion. This printer is currently an area being researched at YSU.

Tech. Specs.

None found.

- Stratasys Fortus 250mc

The Stratasys Fortus 250 mc is a fused deposition modeling (FDM) 3D printer that has the capability to create high resolution prototypes. The Fortus has a larger build volume which allows for larger models to be generated. This reliable machine uses production-grade acrylonitrile butadiene styrene (ABS) thermoplastic material which is coupled with a soluble support structure. This soluble support material allows for complex geometries to be built with ease. YSU thanks the Ohio Board of Regents for the funds provided to acquire the Fortus 250 mc.

Tech. Specs.

-

Material: ABSplus-P430

-

Build Volume (XYZ): 10 x 10 x 12 in (254 x 254 x 305 mm)

-

Layer Thickness: 0.013 in (0.330 mm), 0.010 in (0.254 mm), 0.007 in (0.178 mm)

-

Support Structure: Soluble

-

Size (XYZ): 33 x 29 x 45 in (838 x 737 x 1,143 mm)

-

Weight: 409 lb (186 kg)

-

Achievable Accuracy: ± 0.0095 in (± 0.241 mm)

-

Software: Insight and Control Center

-

- Up Mini

The Up mini is a reliable and user friendly fused deposition modeling (FDM) desktop printer. This 3D printer has a very compact design which is useful for transportation. The Up mini generates strong and reliable prototypes that take up a very small volume. Not only is the printer small, but it also operates at the low volume of 54 dB while building plastic models with strong support structures.

Tech. Specs.

- Build Volume(LxWxH): 4.7 x 4.7 x 4.7 in (120 x 120 x 120 mm)

- Layer Thickness: 0.2/0.25/0.30/0.35 mm

- Size (LxWxH): 9.5 x 13.4 x 14 in (240 x 340 x 355 mm)

- Average Operational Noise: 54 dB

- ProX DMP 320

3D Systems are the inventors of 3D printing. Their machine, the ProX DMP 320, is a Direct Metal Printer. It prints different alloys of Titanium, Nickel and Stainless Steel. The ProX320 prints to within 50 microns of accuracy or approximately 0.0002 in. It comes with its own specialized software that can be operated on standard Windows operating system.

The capabilities of the machine vary because of the capabilities of the print material, but a wide range of desired variables can be achieved. The build volume is 10.82 x 10.82 x 16.53 in and is capable of printing complex geometries not achievable with conventional subtractive machining technologies.

Tech. Specs.

- Build Volume: 10.82 x 10.82 x 16.53 in (275 x 275 x 420 mm)

- Minimum feature size: 100 µm

- Accuracy: ± 0.1-0.2 % with ± 50 µm minimum

- Weight: 10,500 lb (4,700 kg)

- Size: 93 x 91 x 91 in (235 x 230 x 230 cm)

- Software: DMP Software Suite

- S-Max+

The S-Max+ printer is manufactured by the company ExOne. ExOne, a publicly traded manufacturing technology company, provides 3D printing machines, 3D printed products and related services to industrial customers in multiple segments, including pumps, automotive, aerospace, heavy equipment and energy. The S-Max+ prints very large, complex sand cores and molds and is designed to be used with an industrial microwave. The cores are used for high-temperature casting and more challenging casting applications. Two examples of use are castings with very thin walls and channels. One of the other advantages of this machine is the ability to print vastly different part geometries simultaneously. Also, there are no tools necessary and therefore, no storage needed for tooling. Because of this, the S-Max+ uses space very efficiently and helps to curb overhead expenses.

The S-Max+ is also efficient when it comes to use as well. It is easy to load and has a large job box. The job box measures 70.9 x 39.4 x 23.6 in and the machine features a build speed between 2.12 – 3.00 ft3/h. The XYZ print resolution is accurate to 0.004 in, which allows for

precision printing. This particular printer has two job boxes so one can be cleaned while the other is running, resulting in very minimal lost production time because of change over. The consumables for the S-Max+ are binder, activator, ceramic beads, Chromite and Zircon. The casting applications it is most suited for are light metals, non-ferrous metals, cast iron and steel.

Tech. Specs:

- Materials: Silica Sand, Zircon, Cerabeads

- Build Volume: 70.8 x 39.3 x 27.5 in (1,800 x 1,000 x 700 mm)

- Layer Thickness: 280 microns

- Axis Revolution: 100 microns

- Size: 22.6 x 11.4 x 9.1 ft (6.9 x 3.5 x 2.8 m)

- Weight: 14,330 lb (6,500 kg)

HyBrid Manufacturing

- AMBIT

Hybrid Manufacturing Technologies’ AMBIT is a multi-tasking machine like no other. This machine combines the additive manufacturing technology of a 3D printer with the subtracting manufacturing technology of a CNC machine in order to offer the best of both worlds with regard to manufacturing. The AMBIT is centered around the idea that changing from adding material using a deposition head to any selecting of CNC milling heads should be an easy and simple switch. Which the used of the AMBIT being for metal products, this machine is perfectly suited to work with precision for both production and repair projects.

Tech. Specs.

Inquire for more information